AnodizingType II Anodize

Industry professionals employ sulfuric anodizing—an anodizing process that uses a sulfuric bath—to achieve Type II Anodize finishes. These finishes offer good corrosion and wear resistance and are available in vibrant colors.

The Type II Anodize finishes we accommodate are:

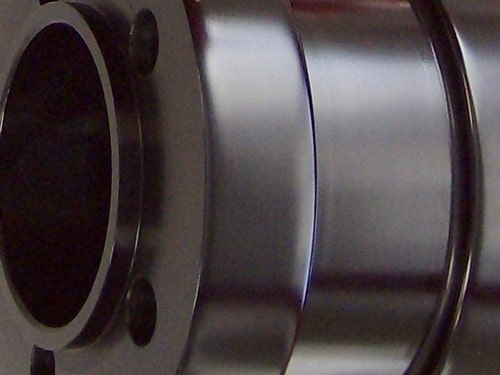

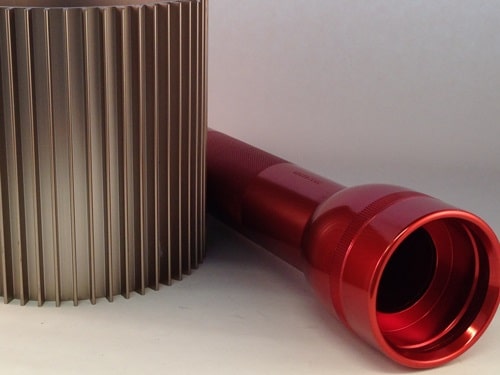

- Bright dip: a highly reflective and glossy finish, similar to a polished finish, that is ideal for use in cosmetic applications

- Clear: a decorative finish that displays the natural finish of the substrate

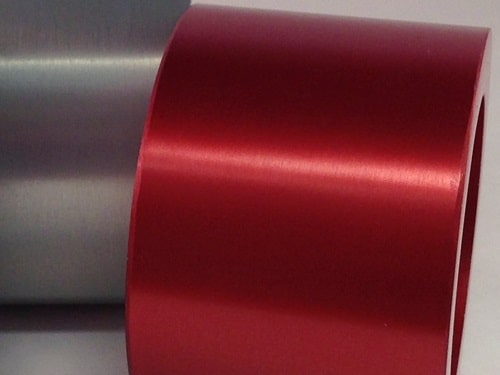

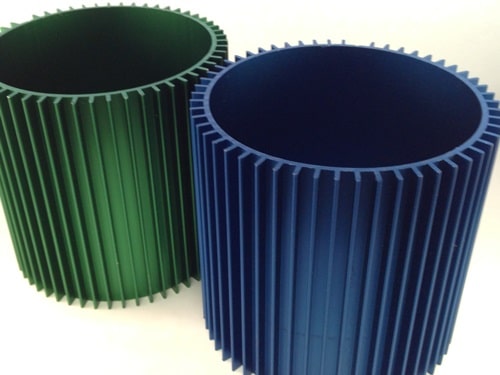

- Dyed: a vividly colored permanent finish

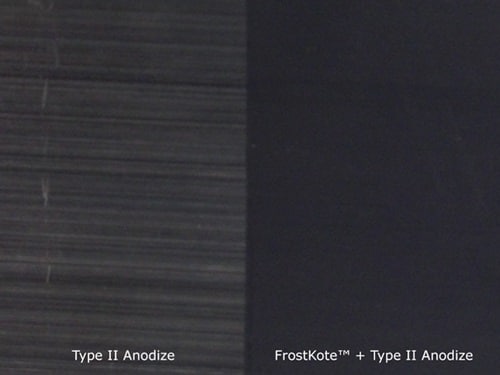

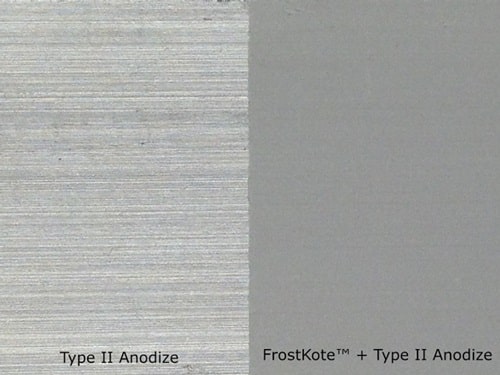

- FrostKote™: a frosted finish that hides surface imperfections (often used as a less expensive alternative to mechanical blasting)