- Why Pioneer

- Processes

- Services

- Metal Finishing Solutions

- Corrosion Resistance

- Premier Anti-Corrosion Solutions

- Wear Resistance

- Adhesive and Bonding Strength

- Rubber to Metal Bonding Adhesives

- Lubricity – Friction Reduction

- Aesthetic Cosmetic Enhancement

- Conductivity

- Dielectric Insulation

- Solderability

- Heat Dissipation

- IR Reduction

- High Reflectivity

- Low Reflectivity

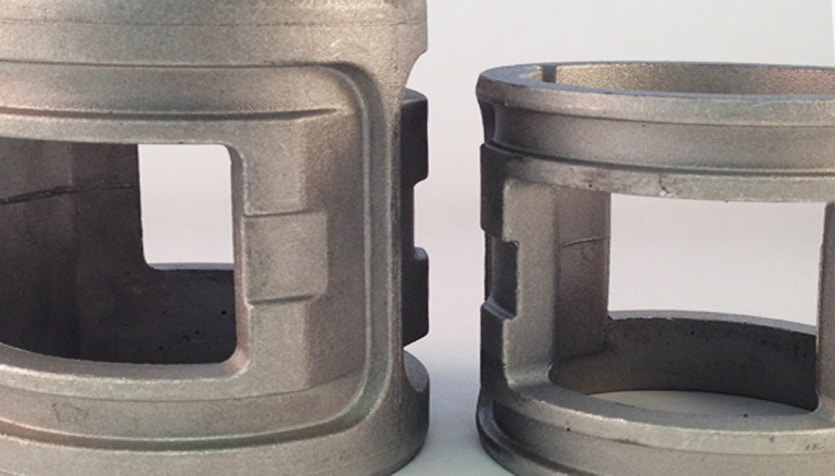

- Aluminum Casting Finishes

- Pioneer Technologies

- Transportation

- Metal Finishing Solutions

- Industries

- Testimonials

- Request a Quote