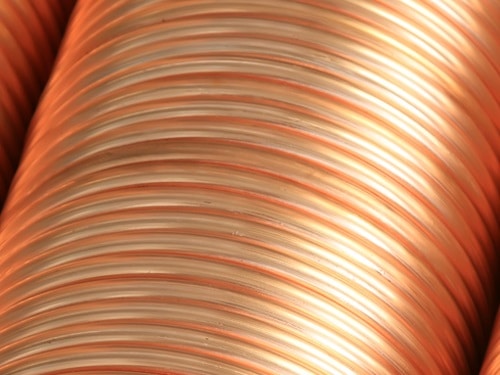

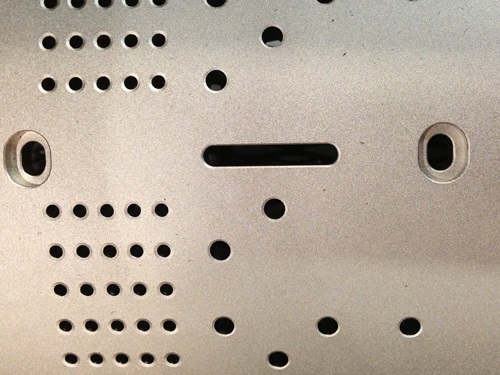

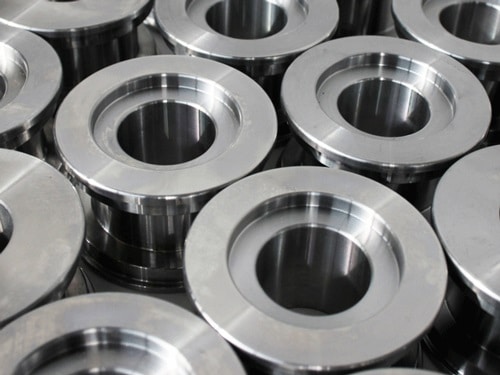

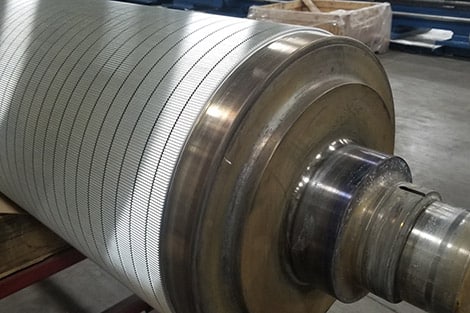

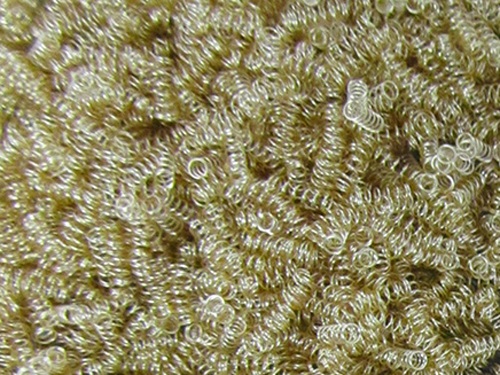

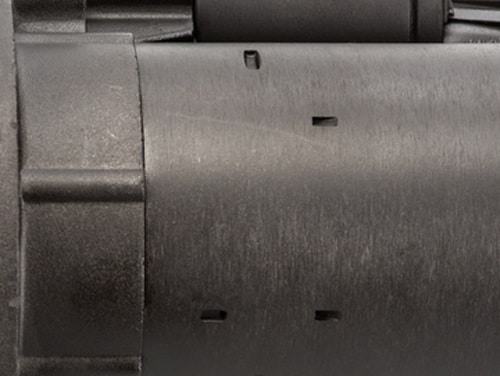

Plating

Plating is the deposition of metals in solutions onto a substrate. Depending on the plating process applied, plating can provide improved corrosion resistance, wear resistance, electrical conductivity, lubricity, solderability, and decorative properties.