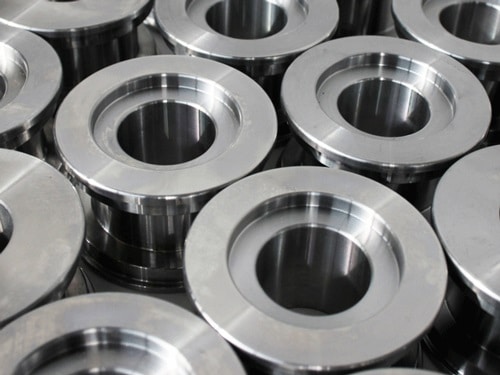

PlatingElectroless Nickel

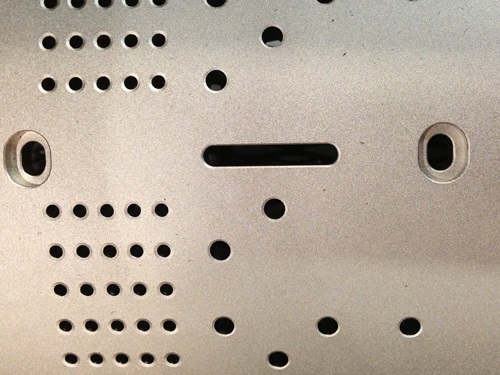

Yielding excellent wear and corrosion resistance, electroless nickel is an autocatalytic plating process resulting in a reflective layer of nickel phosphorous. The total build up plating process provides uniformity on all surfaces, making post machining unnecessary when dimensions are accurate.