Anodizing

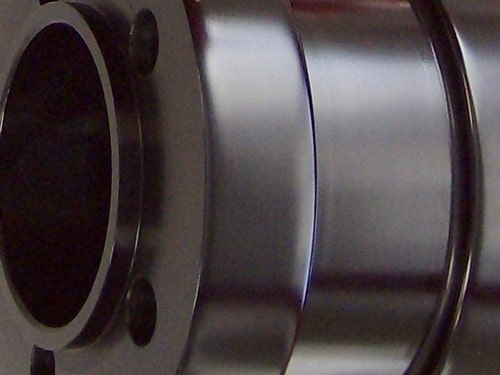

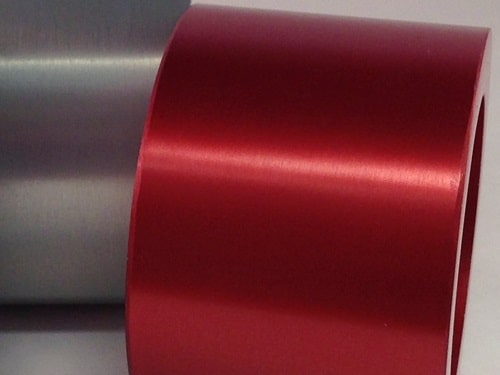

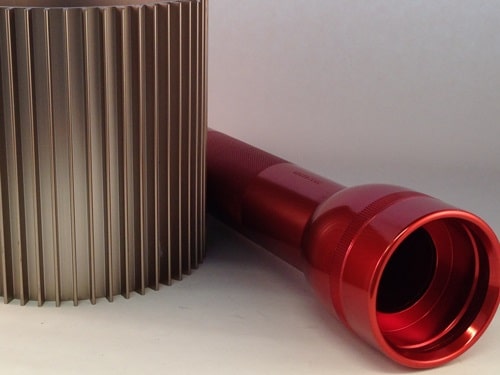

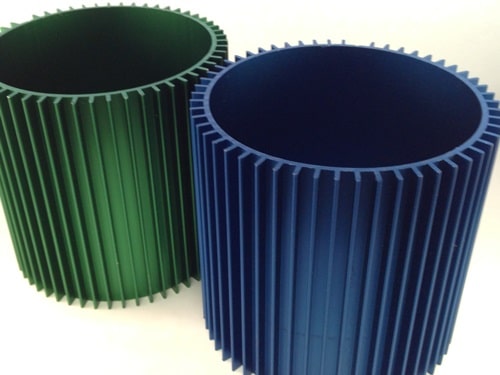

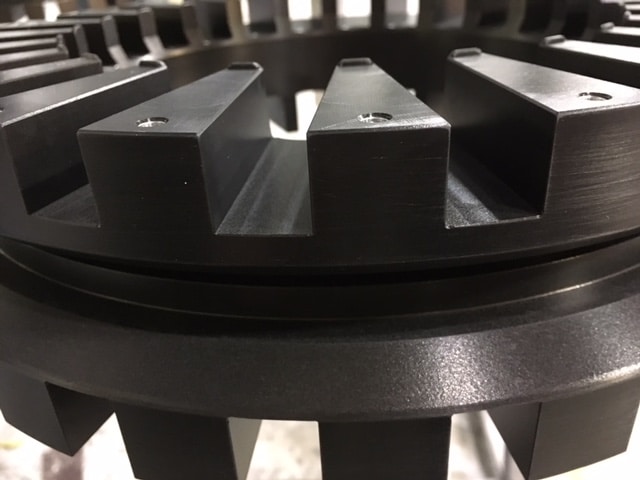

Anodizing is a conversion coating process used to achieve an oxidized surface finish on metal components. It increases the thickness of the naturally occurring oxide layers on metal, enhancing the finished part’s corrosion and wear resistance. Compared to other finishing methods, such as painting or powder coating, the process results in a durable, long-lasting protective layer that is part of the metal rather than sitting atop its surface.

Pioneer Metal Finishing specializes in custom finishing solutions. We offer a broad selection of finishing services to enhance the performance of our customers’ products, including anodizing. Equipped with almost eight decades of industry experience, our team has the skills and knowledge to meet a wide range of anodized part needs.