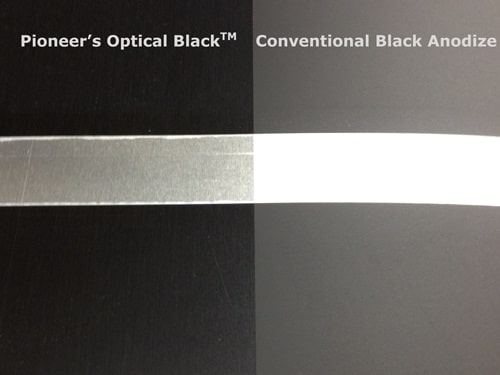

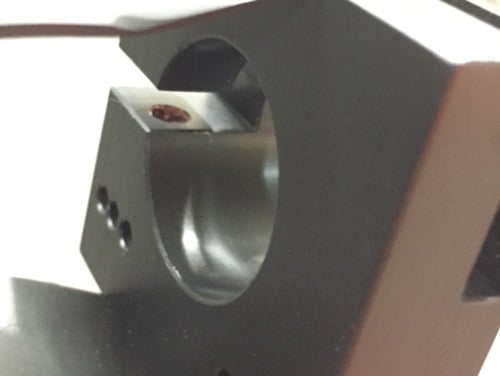

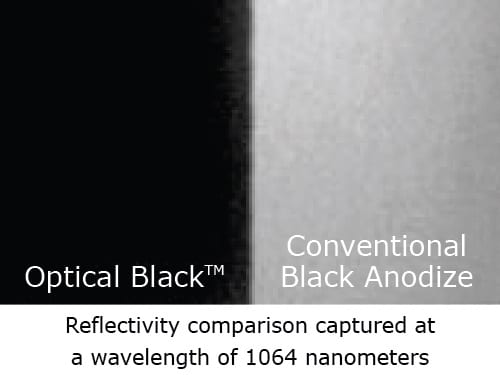

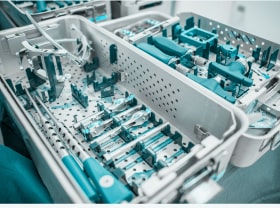

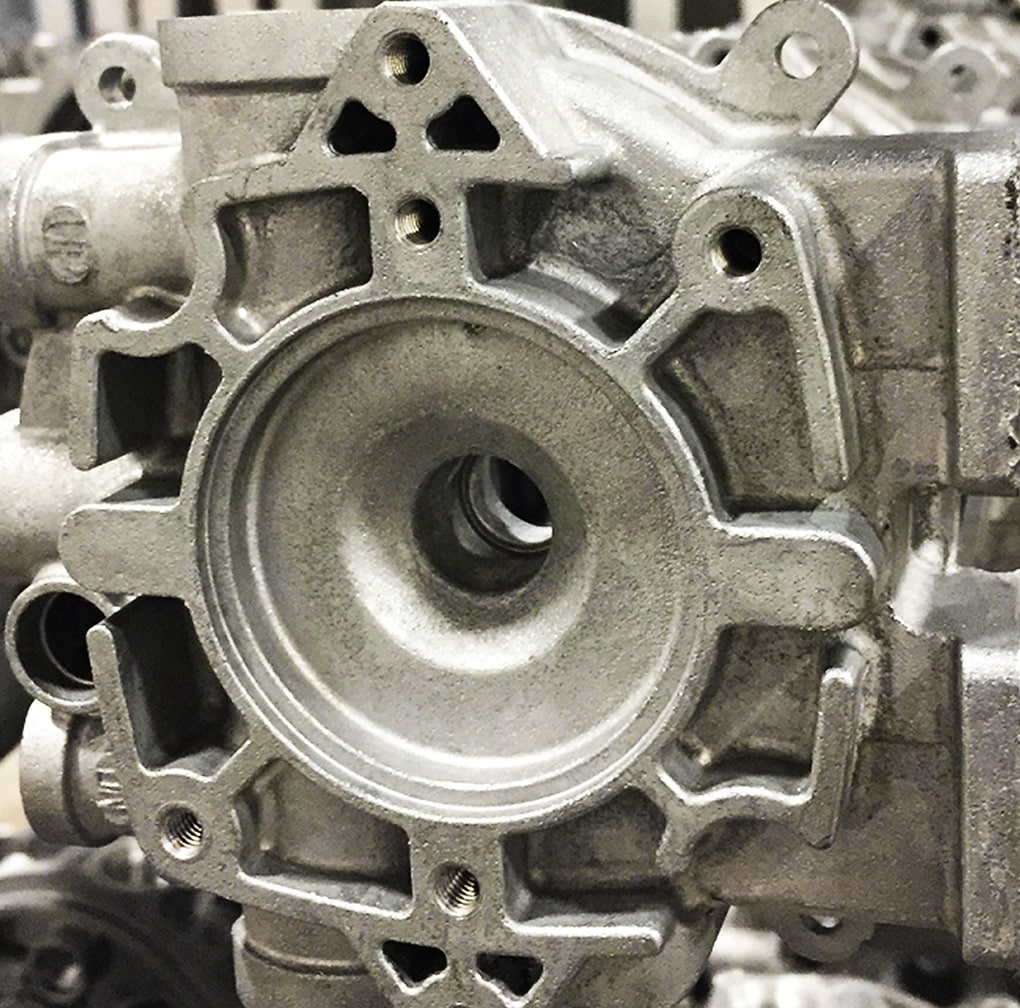

Proprietary Finishing Services

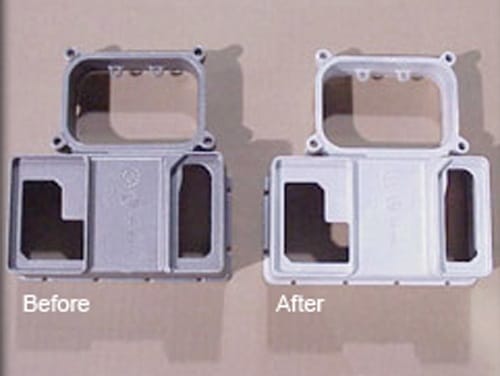

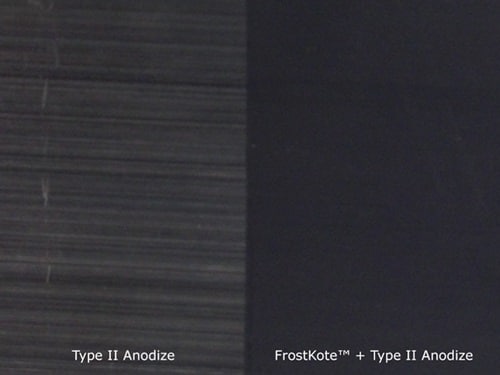

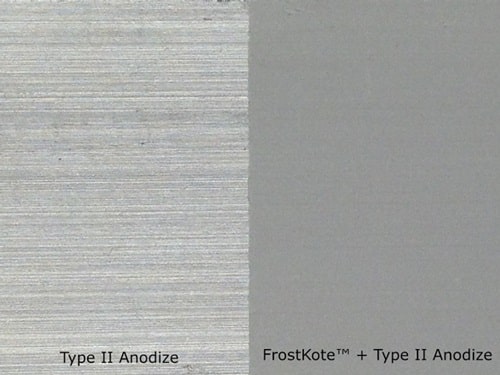

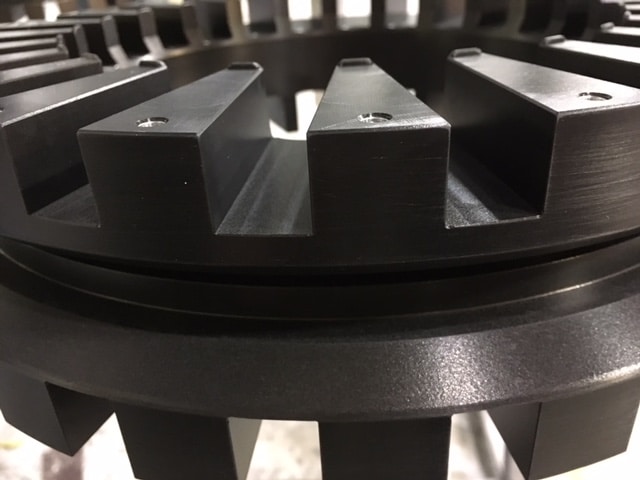

Pioneer has developed special finishing systems to address shortcomings of competitive process offerings in the market. These proprietary finishes allow Pioneer to achieve unmatched coating performance while keeping the costs in line with other standard finishes. Each one of the special Proprietary finishes has been adopted by OEMs, and custom product manufacturers to allow their products to stand out in the marketplace with exceptional performance.